PET (also abbreviated PETE) is short for polyethylene terephthalate, the chemical name for polyester. PET is a clear, strong, and lightweight plastic that is widely used for packaging foods and beverages, especially convenience-sized soft drinks, juices and water. PET typically exhibits low surface energy and poor bonding characteristics. Plasma treatment significantly increases the surface energy of PET resulting in elevated bond strengths.

Knowledge Articles

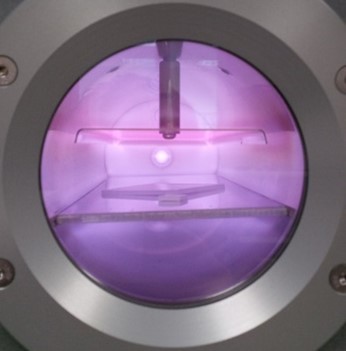

Let’s Talk About… plasma treatment of fluoropolymers

PTFE, and other fluorinated polymers, are chemically inert, thermally stable and highly hydrophobic, due to their intrinsically low surface energy. The chemical inertness of PTFE as an example, means that it is virtually impossible to form lasting adhesive bonds and coatings tend instead to form droplets and 3D particles on the surface rather than a uniform film. Traditional methods to increase the surface energy involve the use of aggressive primers which represent an ecological hazard.

Plasma Cleaning for Organic Solar Cell Fabrication

Efficient carrier-filtering performance probing of oxide buffer-layers in organic solar cell at nanoscale

Materials Library - Acetal

The majority of common engineering polymers have inherently low surface energy and therefore exhibit poor adhesion characteristics. Plasma treatment offers a reliable and environmentally friendly method of both cleaning and activating the polymer surface, increasing the surface energy and wettability, resulting in greatly improved adhesion characteristics.

Materials Library - Nylon

The majority of common engineering polymers have inherently low surface energy and therefore exhibit poor adhesion characteristics. Plasma treatment offers a reliable and environmentally friendly method of both cleaning and activating the polymer surface, increasing the surface energy and wettability, resulting in greatly improved adhesion characteristics.

Materials Library - PVDF

Polyvinylidene fluoride (PVDF) belongs to the group of fluorine-containing thermoplastics whose most well-known member is Teflon® (PTFE) and typically exhibit low surface energy and poor bonding characteristics. Plasma treatment significantly increases the surface energy of PVDF resulting in much elevated bond strengths.

Materials Library - HDPP

The majority of common engineering polymers have inherently low surface energy and therefore exhibit poor adhesion characteristics. Plasma treatment offers a reliable and environmentally friendly method of both cleaning and activating the polymer surface, increasing the surface energy and wettability, resulting in greatly improved adhesion characteristics.

Materials Library - UHMWPE

The majority of common engineering polymers have inherently low surface energy and therefore exhibit poor adhesion characteristics. Plasma treatment offers a reliable and environmentally friendly method of both cleaning and activating the polymer surface, increasing the surface energy and wettability, resulting in greatly improved adhesion characteristics.

Let's talk about... Microfluidics

Microfluidics refers to the behaviour, precise control, and manipulation of fluids that are geometrically constrained to a small scale (typically sub-millimetre) at which capillary penetration governs mass transport. It is a multidisciplinary field that involves engineering, physics, chemistry, biochemistry, nanotechnology, and biotechnology.

What are Microfluidics?

Microfluidics have practical applications in the design of systems that process low volumes of fluids to achieve multiplexing, automation, and high-throughput screening. Microfluidics emerged in the beginning of the 1980s and is used in the development of inkjet printheads, DNA chips, lab-on-a-chip technology, micro-propulsion, and micro-thermal technologies. [1]

Materials Library - Carbon Fibre

Carbon fibre reinforced polymers (CFRP) are formed using both thermoplastic and thermoset polymers and typically exhibit low surface energy and poor bonding characteristics. Plasma treatment significantly increases the surface energy of CFRPs resulting in much elevated bond strengths.