Henniker Plasma, presents the latest and most reliable solutions for reducing wire bonding failures.

Wire bonded silicon chip

Wire bonding is a technique used when creating electrical interconnections between semiconductors, integrated circuits and silicon chips using fine wires. These delicate wires carry the information to the electronic chip. If they fail, the effectiveness of the interconnections between the electronic parts become compromised. Wire bond failure is a major concern for many semiconductor and electronics manufacturers.

Presence of Contamination is a Common Cause of Wire Bonding Failure

Bond Pad Contamination

Wire bond failure can occur when the fine wire bonds are unable to connect efficiently to a bond pad. Halogen and silicone contamination can cause corrosion and impede adhesion. The formation of corrosion by-products can also become damaging, especially if present at the time of bonding.

Diagram of a typical wire bond

Lead Frame Contamination

The lead frames used in the semiconductor device assembly process need to be completely contaminant free. Contamination on the contact surfaces of lead frames can cause a reduction in the quality and provide insufficient bond formation which ultimately impedes adhesion, resulting in complete failure of the whole integrated circuit.

Cu (Copper) lead frame

Plasma Cleaning Solutions

Plasma cleaning is regarded as something of an industry standard for wire bonding, efficiently removing organic contaminants and thin oxide layers under high throughput conditions, quickly, efficiently, and reproducibly, greatly enhancing yield and reducing bond failures.

Henniker Plasma is the leading UK manufacturer of plasma treatment systems for cleaning, surface activation to improve adhesion, and functional nano-scale coating. Henniker’s systems are known for their reliability and delivery of ultra-fine surface preparation.

The Henniker Plasma range

Plasma Cleaning Process

Plasma cleaning can be applied as an in-line solution e.g., prior to encapsulation, or as a batch processing step, with bespoke frame loading arrangements.

Batch processing involves parts being loaded into a plasma chamber. The process is quick and effective, taking no more than 5mins to complete the treatment.

Alternatively, an atmospheric plasma torch system, such as Henniker’s Cirrus unit, can be integrated into an in-line assembly and fully controlled by the host system to achieve localised bond-pad treatment.

Henniker atmospheric system ‘Cirrus’

Plasma cleaning utilises oxygen, argon, hydrogen, or mixtures of these gases. Combinations of these gases are suitable for nearly every case, however there are considerations such as the dulling of lead-frames when using oxygen, or the re-deposition of metal particles in the case of argon, as well as safety concerns when sing hydrogen. Henniker have developed a simple, low-cost alternative method based on plasmas generated using water vapor, which effectively removes contamination and reduces oxide layers without any potential drawbacks.

50:50 Water vapor plasma treated coin

Wire Bond Test Results

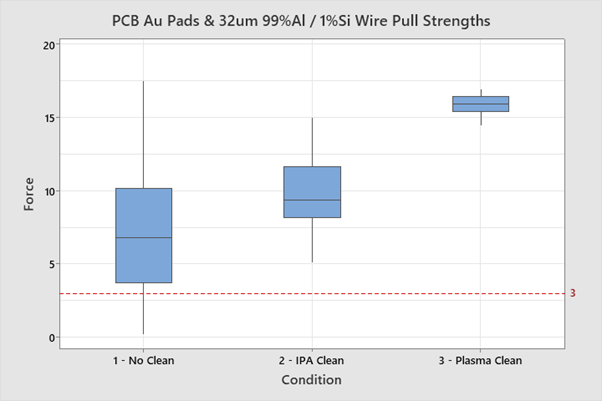

Following plasma treatment, wire bond strength is evaluated using both Destructive Pull Tests (DPT’S) and Non-Destructive Pull Tests (NDPT’s).

The results below compare pull strengths for different cleaning methods and clearly demonstrate both the significant bond improvement and the reduction in variability that can be achieved using plasma cleaning.

Comparison of the effect of different cleaning methods on the pull strength of wire bonds using Henniker’s HPT-300 plasma system

Real-world Application – Solid State Supplies

Henniker’s plasma systems have been in operation at ‘Solid State Supplies’ manufacturing facility in UK for a number of years. Solid State Supplies offer end-to-end solutions for optoelectronic and display assemblies.

Before and after plasma treatment

“Wire bond failure rates have been extremely low while the Henniker Plasma cleaner has been in operation at Solid State. Operation of the machine has been trouble-free with excellent reliability.”

To learn more about wire bonding and plasma treatment contact us today.