As a leading provider of innovative plasma surface treatment solutions, we understand the critical role that surface testing plays in ensuring product quality, performance, and reliability. Whether you are seeking to evaluate surface cleanliness, adhesion strength, wettability, or other surface properties, our comprehensive range of surface test equipment is designed to meet your needs.

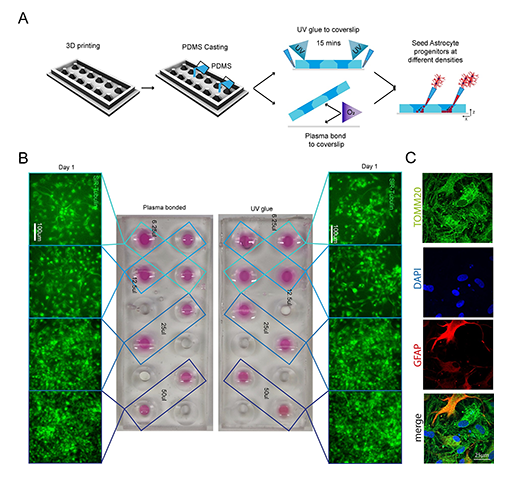

Dyne Test Overview

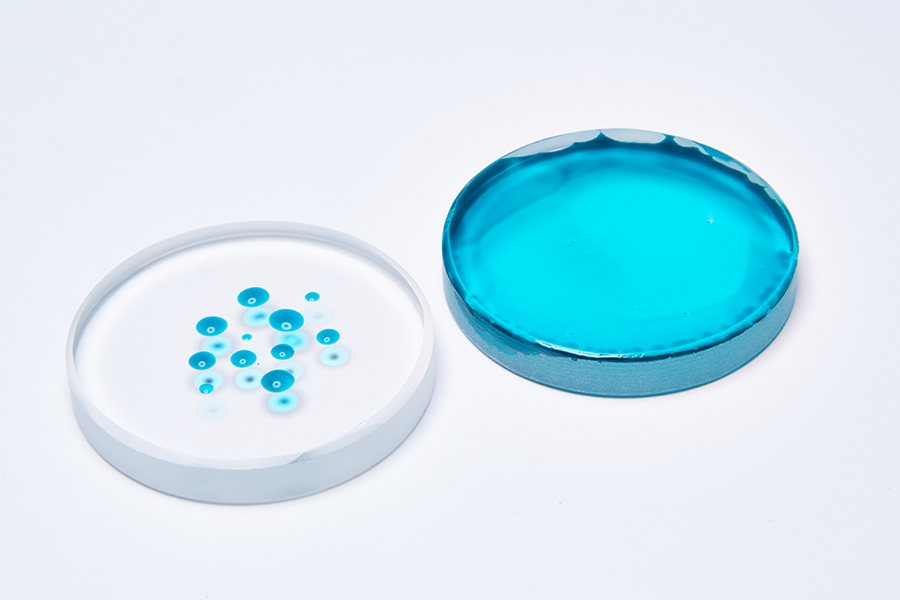

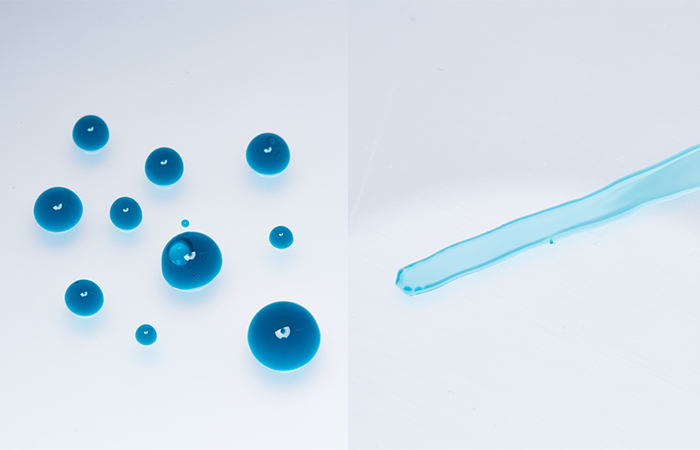

Dyne liquids allow rapid assessment of surface energy. Surface energy is the property of a surface arising from unbalanced molecular forces at or near the surface, compared to those in the bulk material, and provides a quick indication of adhesion characteristics and wettability.

If a liquid is applied to the surface and its surface energy is higher than the surface energy of a material to which it is applied then the liquid tends to form droplets. If the surface energy of the liquid is lower than that of the surface to which it is applied it will spread out or “wet” the surface evenly.

This is the basis of the Dyne test.

Quick Test Dyne Pens - Rapid Surface Testing.

Dyne Pens Sets - Accurate Surface Testing.

Dyne Ink Sets - Surface Energy Test Inks.

Surface Silicone Contamination Test Kit

![]()

Silicone contamination of surfaces poses a real problem in many manufacturing steps. Silicones can be present due to mould release agents or simply from leeching from ‘clean’ packaging, resulting in poor adhesion and bonding characteristics.

Our surface silicone contamination test kit is a convenient method to determine the presence of silicones. Supplied in a handy case, the kit contains everything needed to perform a simple test for surface contamination by silicones.

The test kit contains:

- Wash solvent

- Mineral glass slides

- Over-spray

- Padded carry case

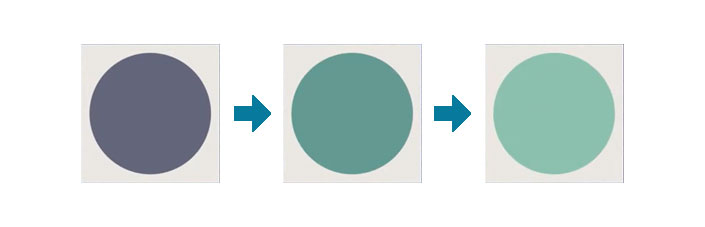

Colour change plasma indicator labels

Available in a range of sensitivity levels, our Plasma Indicator Labels are an indispensable tool for any operation where surface treatment integrity is paramount. They are easy to apply, require no additional equipment, and provide results within seconds, streamlining your quality assurance process and saving valuable time.

Each label is carefully formulated to react to specific surface energy thresholds, changing colour to signify whether the surface has achieved the desired energy level. This immediate visual feedback is crucial for maintaining consistent quality control during production runs and for validating surface preparation before further processing or coating applications.

Plasma indicators from non-treated to effectively treated.