Advancing Peripheral Nerve Regeneration: Leveraging Plasma Surface Activation for Biomaterial Enhancement

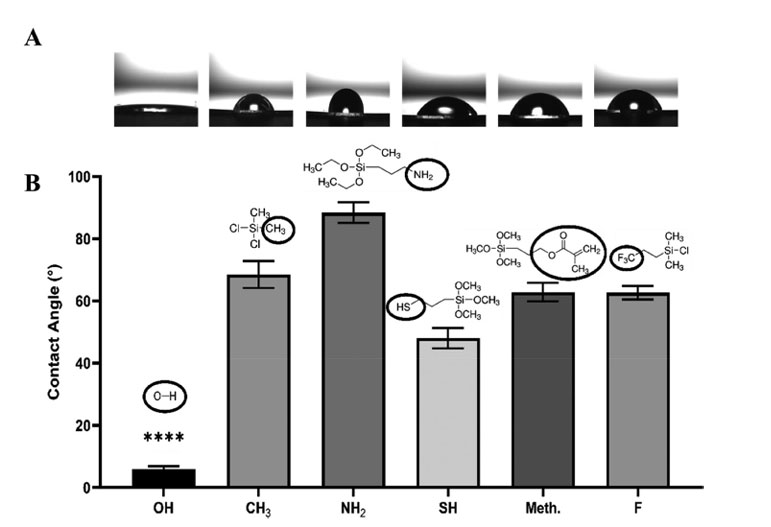

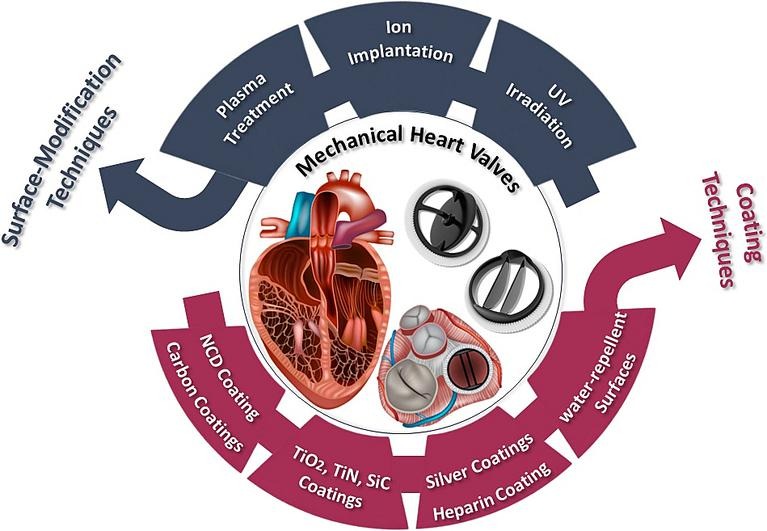

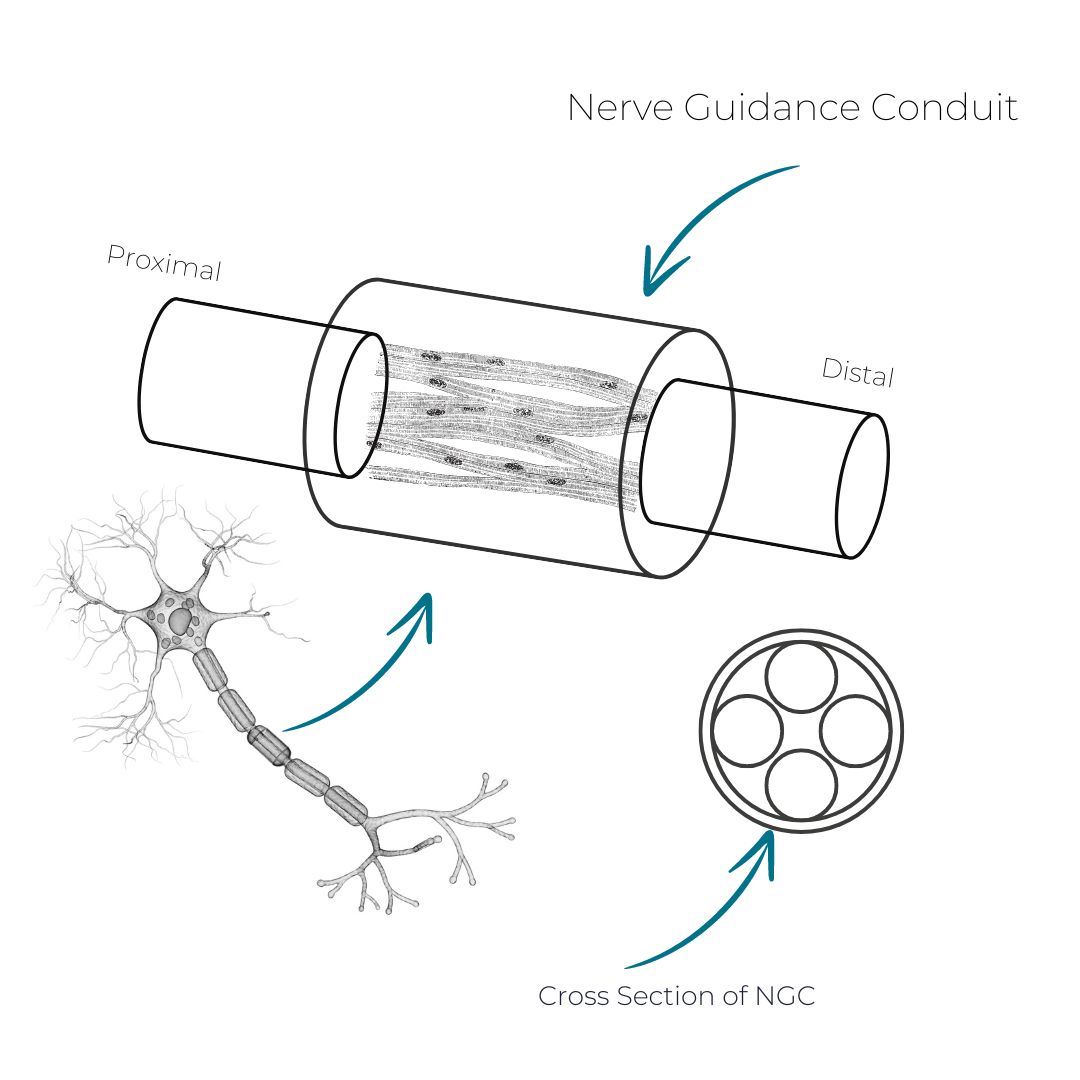

Peripheral nerve injuries pose significant challenges, impacting millions worldwide and necessitating effective treatment strategies. While nerve guidance conduits (NGCs) offer promise, current approaches often fall short in mimicking the complexities of natural tissue, hindering optimal nerve regeneration. Electrospun fiber scaffolds, particularly those crafted from Polycaprolactone (PCL), have emerged as potential solutions but require surface modifications to enhance cellular interactions crucial for successful regeneration.

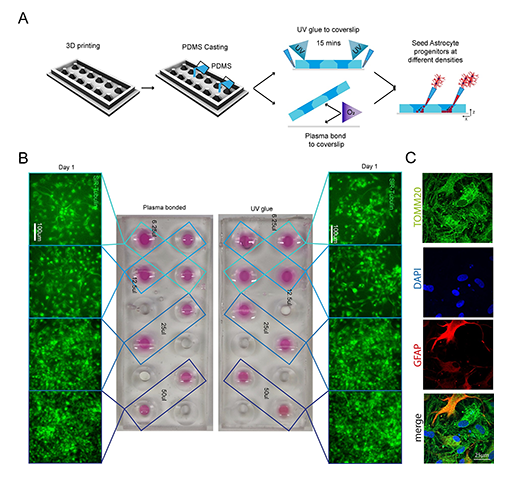

In a study led by researchers from the Department of Materials Science & Engineering at the Kroto Research Institute, University of Sheffield, and the Department of Mechanical, Materials, and Aerospace Engineering at the School of Engineering, University of Liverpool, a novel method was employed to bolster PCL scaffolds for nerve regeneration.