PTFE, and other fluorinated polymers, are chemically inert, thermally stable and highly hydrophobic, due to their intrinsically low surface energy. The chemical inertness of PTFE as an example, means that it is virtually impossible to form lasting adhesive bonds and coatings tend instead to form droplets and 3D particles on the surface rather than a uniform film. Traditional methods to increase the surface energy involve the use of aggressive primers which represent an ecological hazard.

Fluorinated Polymers | PTFE

Fluorinated polymers are not readily modified by standard plasma processes. Oxygen plasmas, which are successfully used to treat many hydrocarbon-based polymers, are not successful because the binding energy of the fluorine to carbon atom is far higher than that of oxygen to carbon. Plasma treatment of fluorinated polymers with oxygen plasmas instead causes a gradual etching of the surface, as opposed to surface activation.

The use of hydrogen plasma on the other hand, produces an immediate and lasting change in the nature of the fluoropolymer surface. The action of atomic hydrogen, generated by the plasma, is to react with surface fluorine and remove this into the gas phase where it is pumped away by the vacuum system. Hydrogen then terminates the free surface bonds to produce a CHx polymer surface which is readily wettable. The resulting surface is also mildly-etched on a microscopic scale which produces a microscopically structured surface. Both actions in combination result in a modified surface which may be glued, painted etc.

Typical results

Results below show the change in morphology, water contact angle and surface energy obtained for PTFE following hydrogen plasma treatment.

The surface energy of PTFE that has been plasma treated is actually lower than that of many common polyolefins, such as polyethylene and polypropylene, and well within the range of wettability required for many adhesives to form strong bonds.

145° Water contact angle for untreated PTFE (Surface Energy 10mN/m)

54° Water contact angle for treated PTFE (Surface Energy 51mN/m)

PTFE Surface morphology before and after hydrogen plasma treatment.

Untreated PTFE

Untreated PTFE H2 Plasma Treated PTFE

H2 Plasma Treated PTFE Visual comparison of surface wettability of PTFE before and following hydrogen plasma treatment.

Untreated PTFE

Untreated PTFE H2 Plasma Treated PTFE

H2 Plasma Treated PTFE Plasma Process

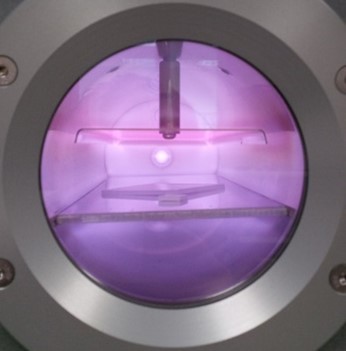

When gas atoms are ionised, the collision of high energy particles knocks electrons out of their orbits. This results in the characteristic “glow” or light associated with plasma. Plasmas many different species including atoms, molecules, ions, electrons, free radicals, metastables, and photons in the short wave ultraviolet (vacuum UV or VUV) range.

Plasmas are generated in closed vessels at low pressures, typically < 1.0 Torr. The low pressure results in a long mean free path of the plasma species, so that they remain reactive until contact with a surface. The overall chamber temperature at the commonly used power levels and pressures is close to room temperature.

Henniker HPT-100 Plasma Treatment System

“Treatment of PTFE with low pressure hydrogen plasma is a very effective method of rendering the surface wettable without using harsh chemicals.“

Please contact us today if you would like to learn more about any of the topics discussed above.