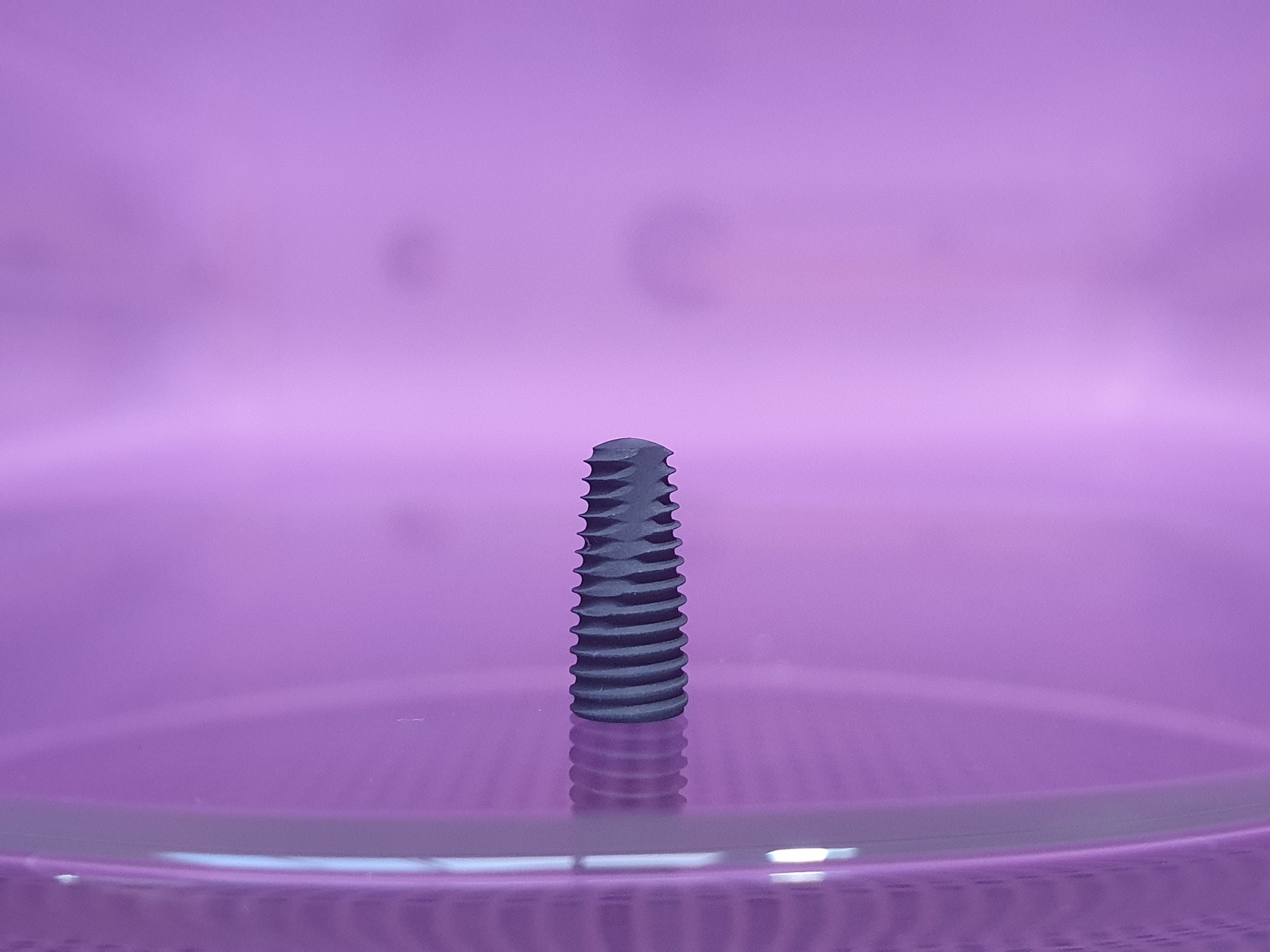

Plasma surface treatment of dental prosthetic structures (implant posts for example) has, for over a decade [1], been demonstrated to remove contamination and increase wettability which results in stronger bonding over the long-term.

Improving the chemical and physical interaction of dental implants with dental adhesives helps to promote the long-term success of such implants. Removal of organic contamination and increased wettability of the implant surface are key factors which can be improved using plasma technology.

Plasma surface treatment using a gas mixture of argon and oxygen is extremely efficient at removing organic contamination and increasing the surface energy (improved wettability) of dental implants. The plasma treatment can be carried out chair-side with a small benchtop vacuum plasma, such as the HPT-100, which has been demonstrated to produce a significant increase in surface wettability when compared with e.g. piezoelectric plasma discharges [2]. Other benefits of vacuum plasma for dental implant applications are:-

- Completely conformal treatment of the entire 3D surface

- Homogeneous and repeatable surface treatment that isn’t influenced by environmental factors

- One-touch automated process that doesn’t rely on operator skill and manual guidance

[1] Clinical Oral Implant Research, 22(9), 2011: 1082-3

[2] Plasma 2021, 389-398.

A recently published article where the Henniker HPT systems are used for dental research can be accessed from the following link:-

Plasma Treatment for Dental Applications

- Plasma activation of dental implants for improved wettability

- Improving bonding during colouration

- Fine cleaning of surfaces before veneering and application

Plasma Surface Treatment for Dental Applications

Plasma surface treatment of dental prosthetic structures (implant posts for example) has, for over a decade, been demonstrated to remove contamination and increase wettability which results in stronger bonding over the long-term.

Relevant Resources