What is Plasma Treatment?

Plasma treatments are used to alter the surface properties of a wide range of materials to make them easier to bond, glue and paint. By treating parts we both clean and activate the surface, improving their adhesion characteristics.

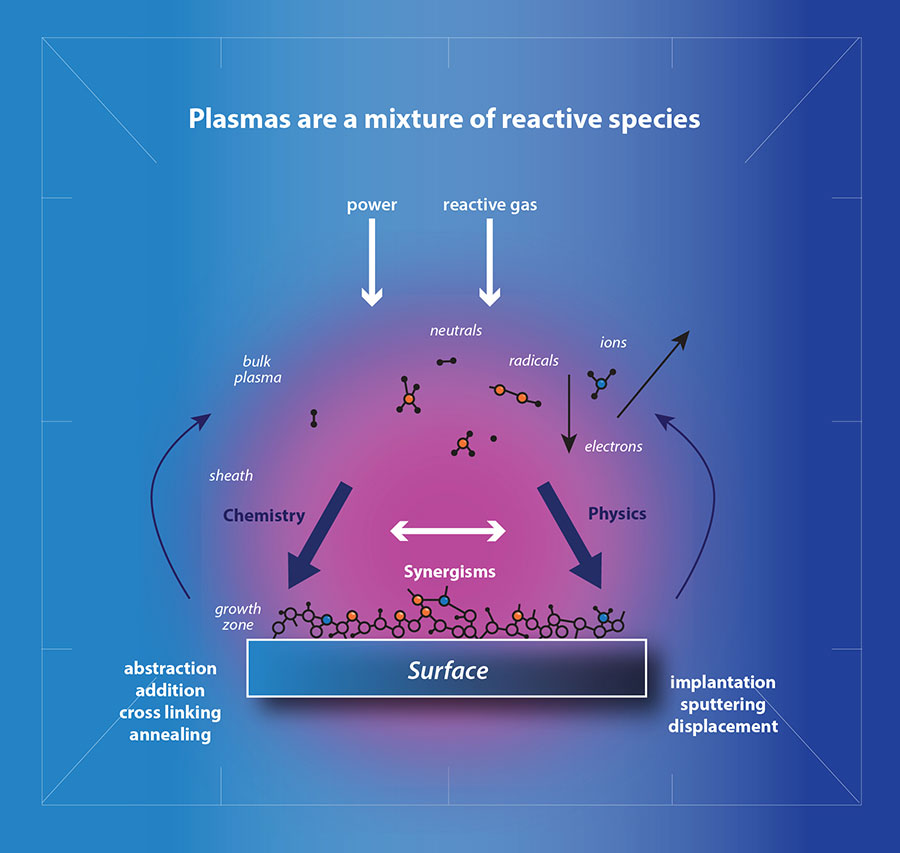

It’s useful to start by defining what a plasma is. Solid, liquid and gas are the three states of matter we are all familiar with. We can move between the states by adding or removing energy (e.g. heating/cooling). If we continue to add enough energy, gas molecules will become ionised (lose one or more electrons) and so carry a net positive charge. If enough molecules are ionised to affect the overall electrical characteristics of the gas the result is called a plasma. Plasmas are, therefore, quite rightly, often referred to as the fourth state of matter.

A plasma contains positive ions, electrons, neutral gas atoms or molecules, UV light and also excited gas atoms and molecules, which can carry a large amount of internal energy (plasmas glow because light is emitted as these excited neutral particles relax to a lower energy state). All of these components can interact with the surface during plasma treatment. By choosing the gas mixture, power, pressure etc. we can quite precisely tune, or specify, the effects of the plasma treatment.

Plasma Treatment Technology Explained

What is Plasma Treatment Technology?

The first in a series of videos about plasma treatment technology, this video explains what plasma treatment technology is and what it can do.

How the plasma treatment process works

Plasma treatment can be performed in an evacuated enclosure or chamber. The air is pumped out and gas is allowed to flow in at low pressure before the energy in the form of electrical power is applied. It’s important to note that the plasma treatment is actually a low-temperature process, meaning that heat-sensitive materials can be processed quite readily.

WHY NOT REQUEST ONE OF OUR FREE INFORMATIONAL POSTERS ‘WHAT IS PLASMA TREATMENT?’

OUR IN-DEPTH GUIDE TO PLASMA PROCESSES AND HOW IT COULD HELP YOU.

COMMON EVERYDAY PLASMAS INCLUDE:

- Fluorescent lights

- ‘Neon’ signs, and

- Plasma televisions of course

COMMON INDUSTRIAL USES, MATERIALS & APPLICATIONS OF PLASMA TREATMENT INCLUDE:

Industries:

- Aerospace

- Automotive

- Contact lenses & optics

- Filter media

- Medical

- Microscopy

- PCB/Electronics assembly

- O-rings

- Plastic/Loyalty cards

- R & D Academic

- Textiles & Fabrics

Materials most commonly plasma-treated

- Plastics, including PEEK, PTFE, Polypropylene, Polyethylene

- Composites

- Engineering polymers

- Microfluidics PDMS

- Glass, metals & ceramics

Common results of plasma treatment

- Plasma surface cleaning

- Plasma surface activation to improve adhesion

- Plasma coatings, hydrophobic & hydrophilic

- Plasma etching

Plasma Treatment Effects

Plasmas are a ‘soup’ of energetic, highly reactive species that are able to interact with any surface which they contact. By choosing the right configuration and processing parameters we can produce specific effects upon the surface. Plasma Treatments can be categorised as Plasma Cleaning, Plasma Surface Activation, Plasma Coatings and Plasma Etching.