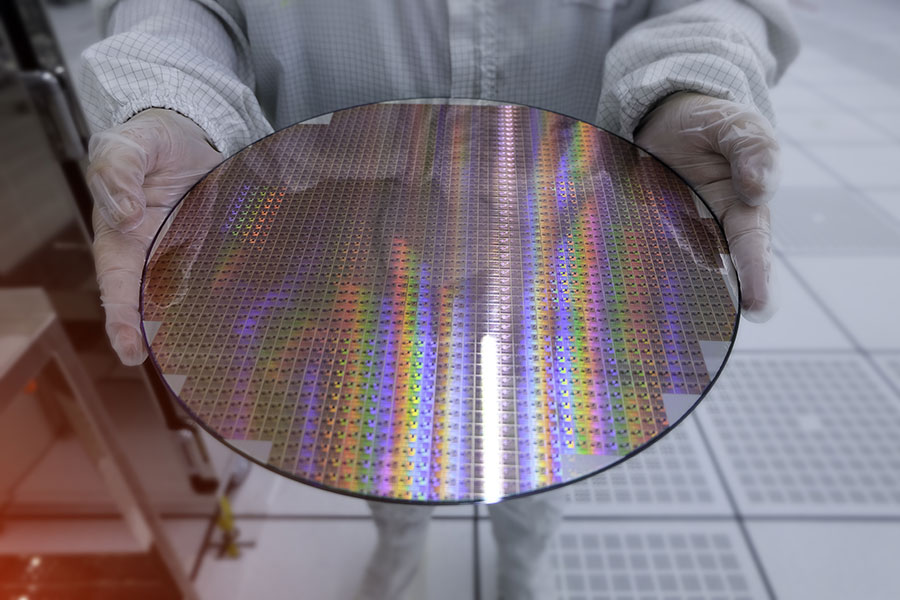

Spin coating is widely used to deposit uniform thin films, typically <10nm. An excess amount of a solution is applied to a substrate which is then rotated to high speeds in order to spread the liquid evenly over the surface by centrifugal force. Spin coating has been widely used for several decades in photolithography, to deposit photoresist on silicon wafers, and the scope has been extended in recent years to chemically engineering the interface of support and solution to obtain specific structural order in the deposited thin films [1].

Several important factors influence film deposition, including viscosity of the deposited solution and spin speed for example. Surface wettability also plays an important role and can be controlled with routine plasma cleaning of the substrate prior to deposition. Henniker’s HPT-100 and HPT-200 bench-top plasma systems are widely used for this purpose to achieve clean, contamination free substrates prior to spin coating.

[1] https://doi.org/10.1016/j.nanoso.2020.100519

A selection of recently published articles where the Henniker HPT systems are used for spin coating can be accessed from the following links:

- Multiscale Hierarchical Surface Patterns by Coupling Optical Patterning and Thermal Shrinkage

- Graphene Oxide Substrate Promotes Neurotrophic Factor Secretion and Survival of Human Schwann-Like Adipose Mesenchymal Stromal Cells

- On the Segmental Dynamics and the Glass Transition Behaviour of Poly(2-vinylpyridine) in One- and Two- Dimensional Nanometric Confinement

- Connecting the density distribution and segmental dynamics of confined polymer films

- Rapid area deactivation for blocking atomic layer deposition processes using polystyrene brush layers

- 2D Titanium Carbide (Ti3C2Tx) in Accommodating Intraocular Lens Design

-

Influence of Surface Roughness on the Dynamics and Crystallization of Vapor-Deposited Thin Films

Related Industries

Relevant Resources