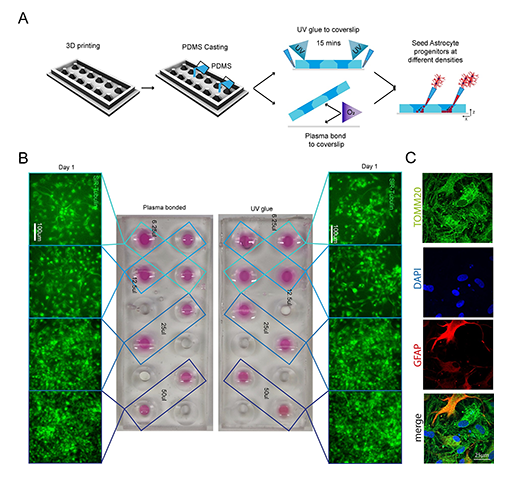

3D printing can create fully customisable imaging chambers with complex well geometry suitable for cell culture via 2 different methods of PDMS bonding.

Image Credit: https://doi.org/10.1371/journal.pbio.3002503

Henniker's HPT-100 plasma treatment system is employed in the protocol for the PDMS bonding process, notably to improve the bonding of the PDMS and the glass coverslips. Treating these surfaces with oxygen plasma enhances their adhesion properties, allowing for a permanent bond when pressed together. Both coverslip and the PDMS were treated for 30s, at 50% and 7sccm. This process, followed by heating to 100º for 20 minutes, ensures a strong and durable bond. Additionally, the Henniker system's role in biofunctionalisation of the micropatterned PDMS substrates is essential for promoting cellular attachment, using the same parameters above researchers are able to achieve consistent results.

Image – The Henniker Plasma HPT-100 System

The versatility of this protocol extends to various applications, including cell alignment and hydrogel culturing systems, potentially leading to a surge in bespoke research tools and a new era of discoveries in biological research.

Join the Conversation

Readers are referred to the original paper published on March 13, 2023, available through the provided DOI link, or click the link below for further details on Henniker Plasma's HPT-100 Plasma Cleaner.

https://doi.org/10.1371/journal.pbio.3002503