Nimbus

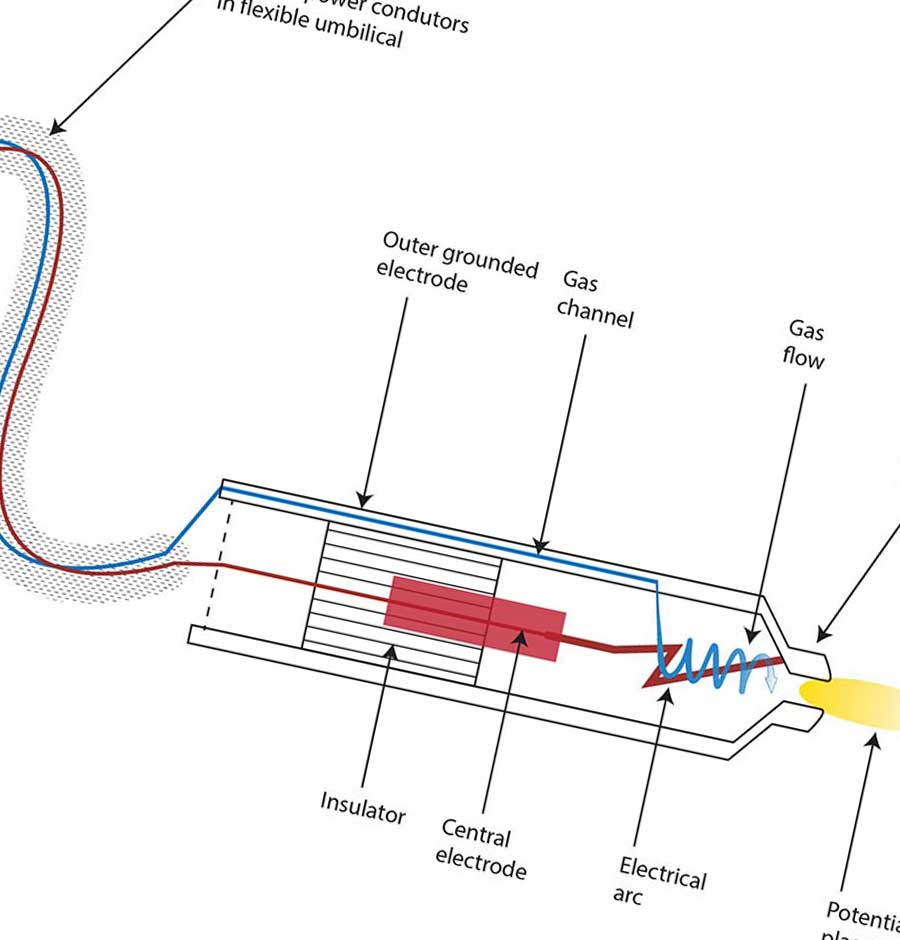

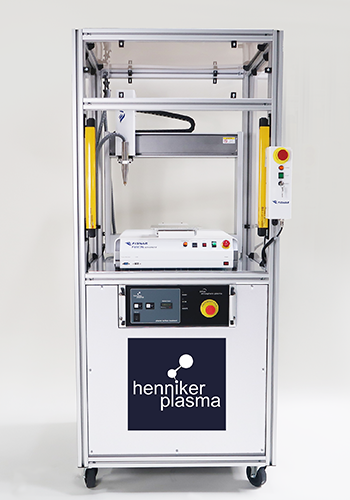

The Nimbus is a dual nozzle atmospheric plasma treatment system ideally suited to surface activation, cleaning and modification of a wide range of materials including polymers, metals, glass and ceramics.

The Nimbus is extremely simple to operate via the front panel soft-keypad and can also be interfaced with external control equipment using the rear panel Sub-D connector providing a variety of I/O control inputs and status read-back to ensure seamless operation with automation lines or robot cells.

The Nimbus operates from a standard single-phase electrical outlet and require only compressed air for operation.

The compact controller features an interlocked airflow regulation unit as standard so that no ancillary equipment is required.

Atmospheric Plasma Advantages

|

Atmospheric plasma systems address a range of specific treatments & material treatments including; plasma cleaning, plasma surface activation to improve adhesion, PEEK & other engineering polymers, PCBs, metals, ceramics and glass. |

|

|

|

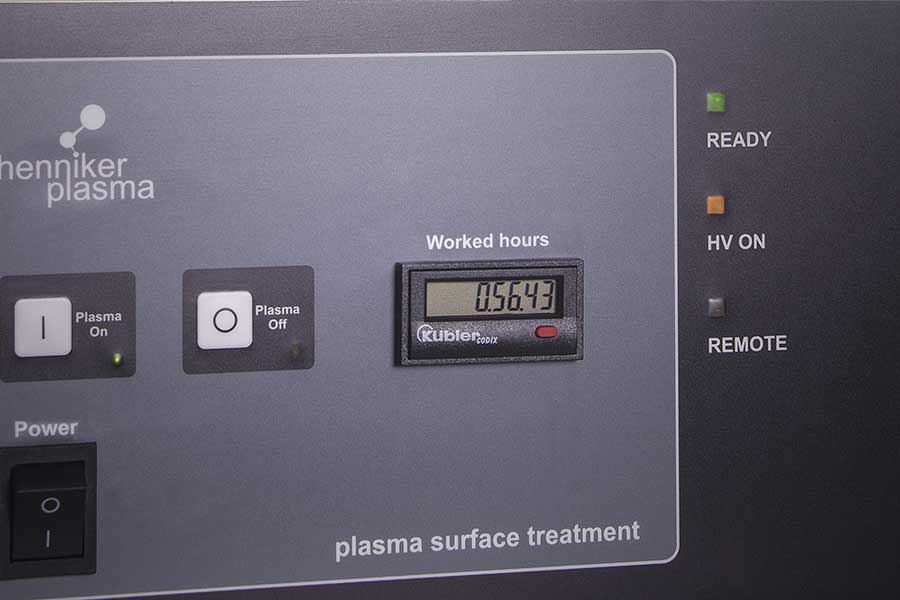

Process Control

Easy operation

The compact control unit can be operated manually or interfaced with existing control equipment. Plasma start and stop signals are supplied via a rear panel Sub-D connector. All important parameters are available on the same connector for read-back and monitoring.

Typical Process Results

Images show increased wettability on metal and polymer samples following plasma treatment.

![Plasma Activated Water [PAW] Application Note](images/knowledgebase/PAW/PAW_Application_Note_-_template.png)