Surface Functionalisation

Vention Medical is a globally integrated solutions partner for the design, engineering and manufacturing of complex medical devices and components. Read about the work completed to activate the PEEK surface of medical devices to improve the PAD printing process enabling complete print adhesion.

Activation to improve PAD print adhesion

Vention Medical is a globally integrated solutions partner for the design, engineering and manufacturing of complex medical devices and components.

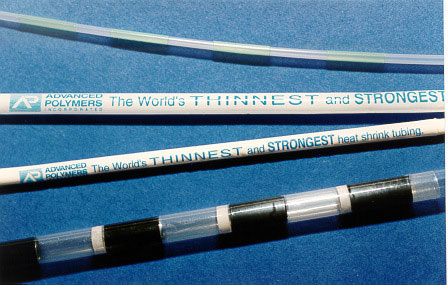

ANSAmed, a Vention Medical Company, provides advanced extrusions and catheter solutions to the global medical device industry. With a focus on continuous product innovation and process improvement, ANSAmed provides a comprehensive design, development and manufacturing services. Operating under stringent quality standards, ANSAmed’s extrusion products and components conform to the tightest possible tolerances. ANSAmed’s range of extrusions include single-lumen, multi-lumen and over the wire extrusion, tapered bump and multi-layer extrusion, balloon tubing, co-extrusion and braided tubing, along with contract medical device design and manufacture. ANSAmed’s custom extrusions and contract medical devices are supplied to the cardiology, peripheral vascular, neurovascular, CVC, urology, respiratory and other clinical markets.

PAD Print Ink Adhesion

ANSAmed sought our advice after discovering issues with the PAD printing of certain medical devices. The medical devices in question required regular, intricate printing & depth marks using the PAD Printing technique, which places a very thin layer of ink onto the surface. In this instance, the medical devices were made of PEEK and included Catheters and Microcatheters, Nasogastric Feeding Tubes & Endotracheal Tubes, among others.

Polyetheretherketone (PEEK) is an engineering thermoplastic with outstanding heat-resistance. The glass transition temperature is 144°C, the melting point 335°C and it is typically melt-processed at 370°C.

These properties, although advantageous to the design engineer, often result in secondary assembly and decorating issues - bonding, printing, coating & painting.

Henniker worked closely with ANSAmed’s Technology Team to identify a solution to these problems.

Our Solution

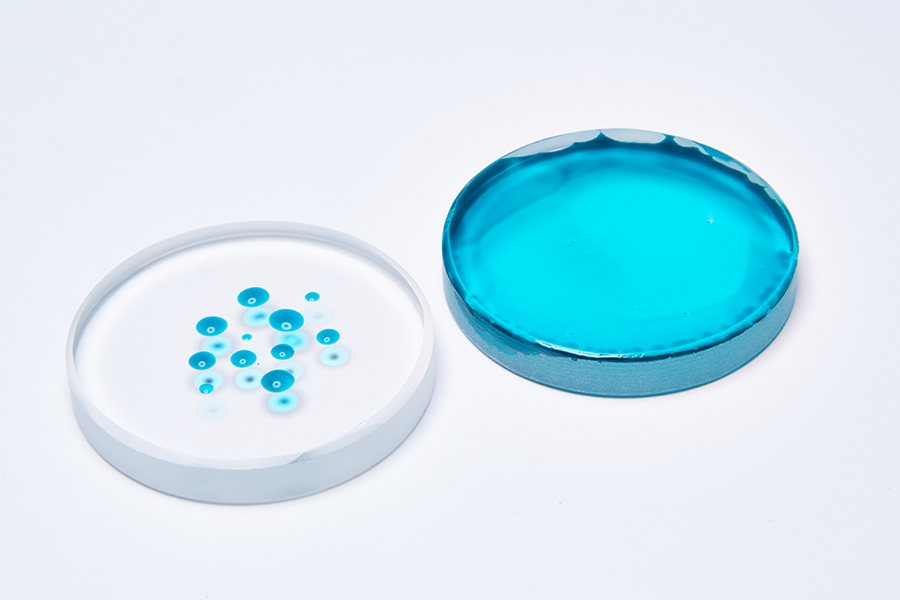

A basic requirement for successful ink adhesion is spreading of the ink on the substrate. Spreading will occur if the surface tension of the ink is lower than the surface free energy of the part. After confirming that there were no underlying contamination issues, our team, first of all, determined the surface free energy of several PEEK devices using a range of in-house surface test methods, a common step in our process development method.

Surface Energy

Surface energy is defined as the excess energy at the surface of a material compared with the bulk material itself. If the molecules of the liquid are attracted to each other more strongly than to the surface then the liquid won’t wet the surface very well, instead of forming beads. Conversely, if there is a larger attraction to the surface then the liquid will spread out more.

It follows that if a particular surface has higher surface energy, it will wet more easily and, since the ability to wet a surface is, in turn, a simple definition of the adhesion characteristics of the surface, it will be easier to glue/print/paint or bond to that surface.

Values of the surface energy of between 30-35 dynes were found for untreated PEEK whereas typical inks used in the process have surface tension values approximately 25% higher than this.

Plasma Surface Treatment

A range of plasma treatments were then investigated to determine the quickest and most cost-effective process to improve the surface wettability of the PEEK devices. After the initial trials were completed we were able to demonstrate a simple and effective process which was able to increase the PEEK surface energy to greater than 72 dynes with a total process cycle time of fewer than two minutes.

Contract Plasma Treatment

We were also able to provide ANSAmed with a contract treatment solution offering a quick turnaround contract plasma treatment service for both their small one-off requests and on-going production. Contract plasma treatment is a cost-effective way of tapping into the unique benefits of plasma treatment where the cost of capital equipment isn’t justifiable, for example where one-off or short term contracts have been awarded.

Complete Satisfaction

A combination of our experience and knowledge relating to low surface energy materials, coupled with our ability to perform rapid testing and quickly develop a suitable process were invaluable to ANSAmed’s Technology Team. The process was quickly transferred to our in-house contract treatment team and continues to serve our client with a rapid, cost-effective solution to their specific printing problem.

“Henniker Plasma treatment has ultimately benefitted our business and will continue to contribute to our successes in the future,”

says Paul O’Donnell, Technology Project Manager.

“Plasma treatment is cost effective, flexible and Henniker’s approach was very helpful in developing arobust process”.

To read the full Case Study click here

REQUEST A QUOTATION OR FURTHER INFORMATION