News - Henniker Plasma

Plasma Surface Activation and Peripheral Nerve Regeneration

Advancing Peripheral Nerve Regeneration: Leveraging Plasma Surface Activation for Biomaterial Enhancement

Peripheral nerve injuries pose significant challenges, impacting millions worldwide and necessitating effective treatment strategies. While nerve guidance conduits (NGCs) offer promise, current approaches often fall short in mimicking the complexities of natural tissue, hindering optimal nerve regeneration. Electrospun fiber scaffolds, particularly those crafted from Polycaprolactone (PCL), have emerged as potential solutions but require surface modifications to enhance cellular interactions crucial for successful regeneration.

In a study led by researchers from the Department of Materials Science & Engineering at the Kroto Research Institute, University of Sheffield, and the Department of Mechanical, Materials, and Aerospace Engineering at the School of Engineering, University of Liverpool, a novel method was employed to bolster PCL scaffolds for nerve regeneration.

Materials Library - PCL

The majority of thermoplastics have inherently low surface energy and therefore exhibit poor adhesion characteristics. Plasma treatment offers a reliable and environmentally friendly method of both cleaning and activating the thermoplastic surface, increasing the surface energy and wettability and resulting in greatly improved adhesion characteristics.

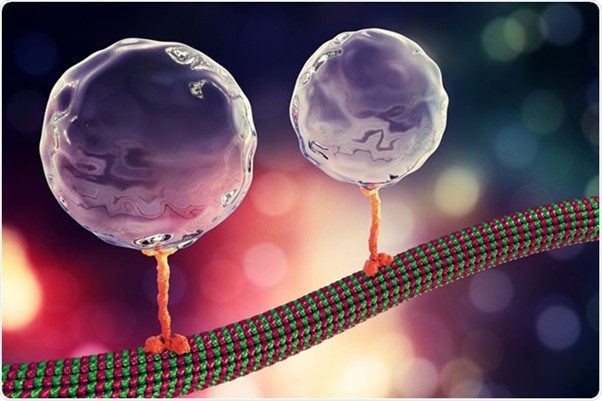

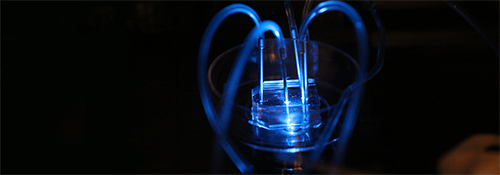

Molecular motors – Advancing Microtubule Dynamics

Intracellular transport relies on the coordinated efforts of molecular motors, particularly dynein and kinesin, which facilitate bidirectional movement along microtubules. Despite the recognised co-dependency between these motors, the underlying mechanisms have remained elusive. In this study, employing in vitro motility assays, researchers at the MRC Laboratory of Molecular Biology, unveil a dual role for the kinesin-3 motor, KIF1C, acting not only as an activator but also as a processivity factor for dynein. Using a Henniker Plasma HPT-200 system specifically in the meticulous preparation of the microscopy chambers used for TIRF (Total Internal Reflection Fluorescence) assays.

The Cost of Cultureware

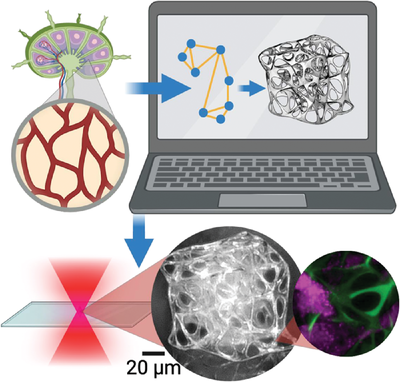

Microprinted 3D Cell Scaffolds: Mimicking Nature's Network Wiring in Lymph Nodes

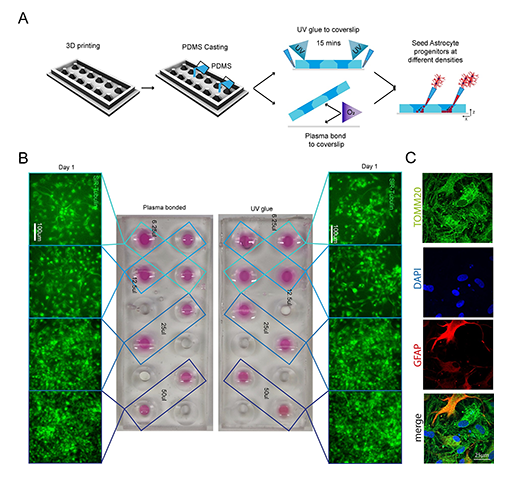

Research conducted on bioinspired 3D microprinted cell scaffolds and recently published in Biotechnology Journal marks a significant shift in tissue engineering and biomedical research. Notably, using a Henniker Plasma HPT-100 system to facilitate the preparation of fused silica substrates through oxygen plasma treatment.

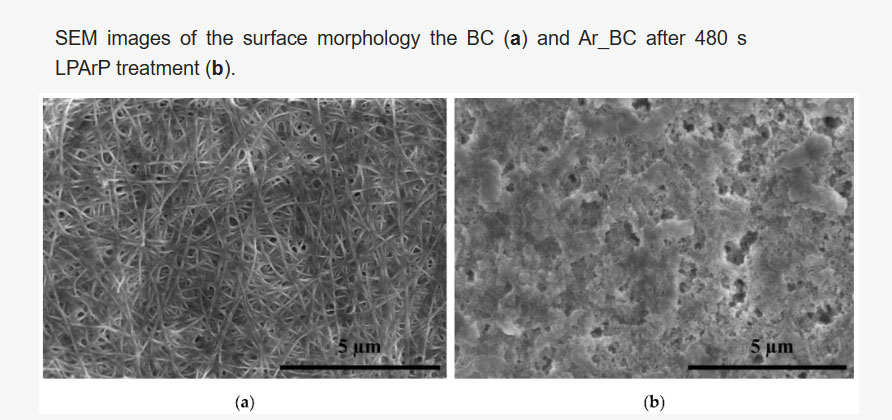

Advancement in Wound Care - Argon Plasma Treatment with the HPT-100

Materials Library - EPDM

The majority of synthetic rubbers have inherently low surface energy and therefore exhibit poor adhesion characteristics. Plasma treatment offers a reliable and environmentally friendly method of both cleaning and activating the rubbers surface, increasing the surface energy and wettability, resulting in greatly improved adhesion characteristics.

Materials Library - Polypropylene

The majority of common engineering polymers have inherently low surface energy and therefore exhibit poor adhesion characteristics. Plasma treatment offers a reliable and environmentally friendly method of both cleaning and activating the polymer surface, increasing the surface energy and wettability, resulting in greatly improved adhesion characteristics.

Advancing Microfluidic Production at The Making Lab, Francis Crick Institute, through precision plasma treatment and PDMS bonding

Established in 2016, The Making Lab at the Francis Crick provides Crick-affiliated researchers with the expertise, training and tools needed to make devices to aid their experiments, while also acting as a forum to share expertise. Functioning as a collaborative hub, the lab hosts engineers, biologists, and industry partners, fostering innovative problem-solving in engineering and biomedical research. With hundreds of collaborative projects since its inception, the lab has become known for advancements in microfluidic devices, amongst others.

The potential of photoactive materials to manipulate surface topography.

Researchers from the Department of Chemistry and Materials Science at Aalto University School of Chemical Engineering explored how photoactive materials can manipulate surface topographies, creating opportunities for various applications such as designing stretchable electronic and advanced optical devices.

Materials Library - Polystyrene

The majority of common engineering polymers have inherently low surface energy and therefore exhibit poor adhesion characteristics. Plasma treatment offers a reliable and environmentally friendly method of both cleaning and activating the polymer surface, increasing the surface energy and wettability, resulting in greatly improved adhesion characteristics.

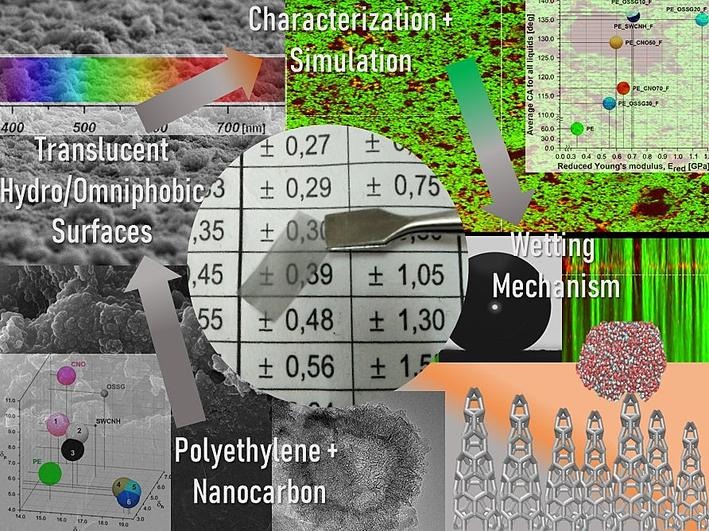

Omniphobic Surfaces with Carbon Nanomaterials and Plasma Technology

The Physiochemistry of Carbon Materials Research Group at Nicolaus Copernicus University in Toruń, have been publishing and completing work to produce new durable, transparent hydrophobic, superhydrophobic and omniphobic surfaces with the aid of modern carbon nanomaterials and a thermal feathering technique developed in a previous study.

Materials Library - High Impact Polystyrene (HIPS)

The majority of common engineering polymers have inherently low surface energy and therefore exhibit poor adhesion characteristics. Plasma treatment offers a reliable and environmentally friendly method of both cleaning and activating the polymer surface, increasing the surface energy and wettability, resulting in greatly improved adhesion characteristics.

Introducing the new look design for our US website

Introducing the new look website design for www.henniker-plasma.com : A fresh digital experience for our overseas market.

Henniker Plasma Enhancing Research Capabilities at The Bridge with the TEM Plasma Cleaner

The Bridge: A Hub of Innovation

The Bridge (Advanced Materials and Engineering R&D Centre) at the University of Lincoln is a centre for innovation in advanced materials that works with local and national businesses to provide education, cutting edge engineering and collaboration. The Bridge works alongside the University of Lincoln to create a network of advanced science and engineering professionals that can work on solving problems through innovation.

Materials Library - Cyclic Olefin Copolymer (COC)

The majority of common engineering polymers have inherently low surface energy and therefore exhibit poor adhesion characteristics. Plasma treatment offers a reliable and environmentally friendly method of both cleaning and activating the polymer surface, increasing the surface energy and wettability, resulting in greatly improved adhesion characteristics.

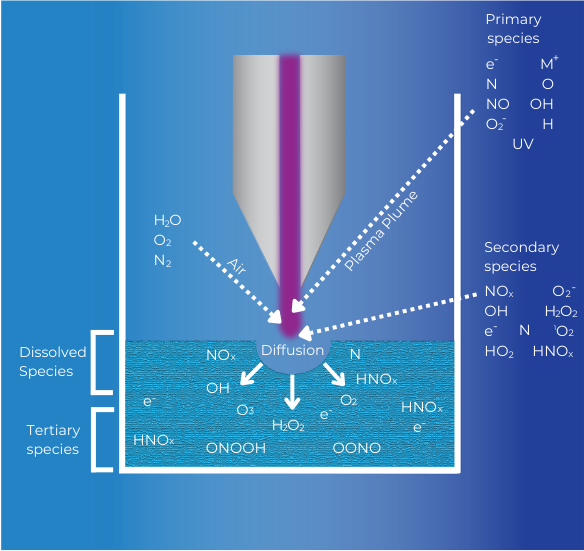

Plasma Activated Water [PAW] Application Note

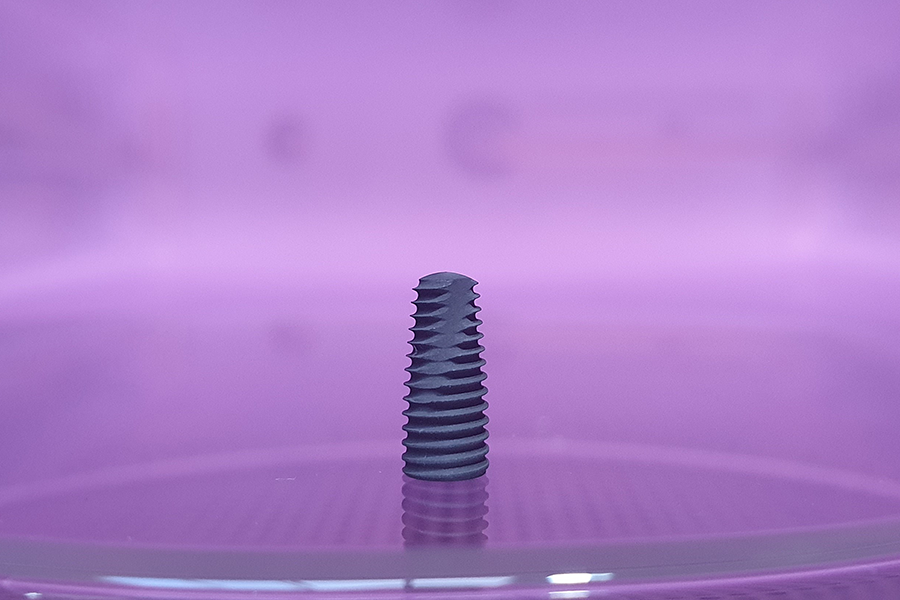

Plasma Treatment to Improve Osseointegration of Dental Implants

Henniker Plasma, a leading manufacturer of plasma surface treatment equipment, presents Plasma Treatment to Improve Osseointegration of Dental Implants.

Let’s Talk About… Plasma Treatment to Improve Osseointegration of Dental Implants

One of the challenges in dental implantology is to achieve a stable and long-lasting connection between the implant and the surrounding bone tissue. This connection, known as osseointegration, depends on various factors such as the implant material, design, surface properties, and surgical technique.