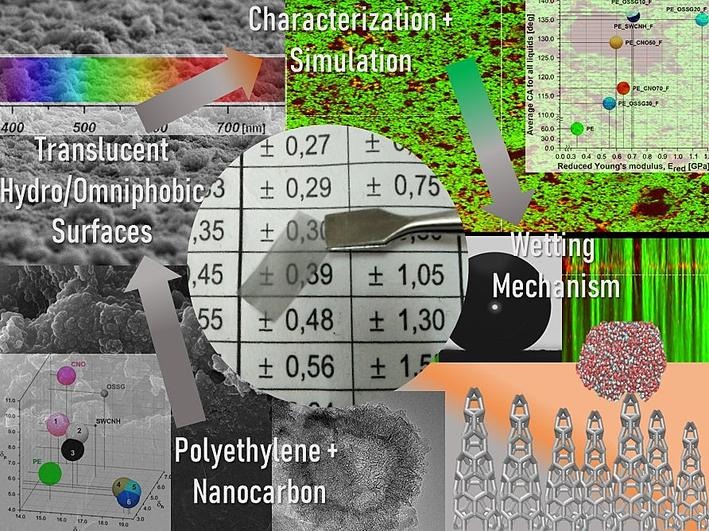

The Physiochemistry of Carbon Materials Research Group at Nicolaus Copernicus University in Toruń, have been publishing and completing work to produce new durable, transparent hydrophobic, superhydrophobic and omniphobic surfaces with the aid of modern carbon nanomaterials and a thermal feathering technique developed in a previous study.

Image Courtesy of https://doi.org/10.1016/j.cej.2023.142237 (https://www.sciencedirect.com/science/article/pii/S1385894723009683)

In this new study, they go a step further to combat issues with waste polymers, by using thermal feathering combined with chemical modification to introduce fluoride groups on the surface. They also employ various carbon nanomaterials (such as spherical carbons, nanoonions etc.) to produce and characterise new transparent surfaces that are highly water-repellent. Furthermore, they show that by fluorination, these surfaces can be transformed into omniphobic surfaces.

Fig. 1. HRTEM images of studied carbon nanomaterials, together with schematic representation of differences in structure - Courtesy of https://doi.org/10.1016/j.cej.2023.142237

(https://www.sciencedirect.com/science/article/pii/S1385894723009683)

Omniphobic surfaces, capable of repelling both water and oils, have garnered significant attention for their multifaceted applications. These surfaces are not only hydrophobic (water-repellent) but also oleophobic (oil-repellent), making them incredibly versatile for various industrial and technological purposes.

Henniker Plasma's technology plays a crucial part in activating the surfaces before the introduction of fluorine. This step is critical to ensure that the fluorine molecules bond effectively with the surface, enhancing its liquid-repelling properties.

Henniker’s HPT-100, known for its precision and reliability, provides the researchers with the means to create the necessary surface modifications. By utilising oxygen plasma, the surfaces are prepared for the subsequent fluorination process, ensuring the successful grafting of fluorine-containing groups onto the surface.

Fig. 2. Hansen Solubility Parameters for the investigated materials. Polymer with CNM is presented for the better understanding how the fluorination process changed the features of the samples - Courtesy of https://doi.org/10.1016/j.cej.2023.142237 (https://www.sciencedirect.com/science/article/pii/S1385894723009683)

The resulting surfaces, as a product of this research, hold immense promise. They combine water and oil repellency with transparency, making them suitable for a wide range of applications. These include self-cleaning coatings that can stay pristine in various environments, protection against corrosion, efficient separation of liquids, and even military applications.

Moreover, the research showcases the importance of developing transparent omniphobic surfaces, as recommended by The American Society for Testing and Materials (ASTM). These surfaces have applications in coatings and the electronics industry, where both liquid resistance and transparency are essential.