Advancing Peripheral Nerve Regeneration: Leveraging Plasma Surface Activation for Biomaterial Enhancement

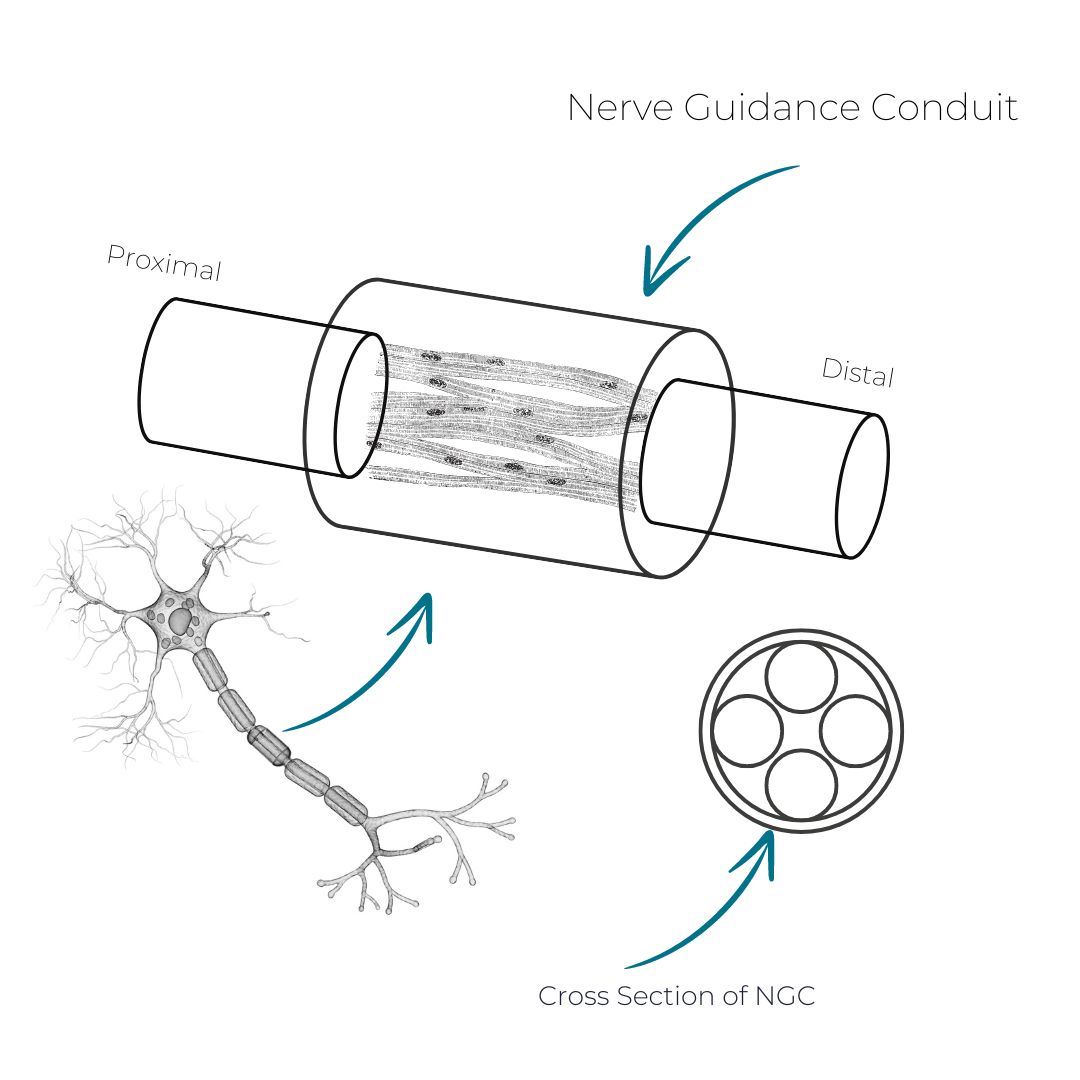

Peripheral nerve injuries pose significant challenges, impacting millions worldwide and necessitating effective treatment strategies. While nerve guidance conduits (NGCs) offer promise, current approaches often fall short in mimicking the complexities of natural tissue, hindering optimal nerve regeneration. Electrospun fiber scaffolds, particularly those crafted from Polycaprolactone (PCL), have emerged as potential solutions but require surface modifications to enhance cellular interactions crucial for successful regeneration.

In a study led by researchers from the Department of Materials Science & Engineering at the Kroto Research Institute, University of Sheffield, and the Department of Mechanical, Materials, and Aerospace Engineering at the School of Engineering, University of Liverpool, a novel method was employed to bolster PCL scaffolds for nerve regeneration.

Polycaprolactone fiber nerve guidance conduits

Polycaprolactone (PCL) fibers are biodegradable and have favourable mechanical properties, making them ideal for tissue engineering. They are easily processed into aligned fibers with high surface area, promoting cell attachment. PCL is biocompatible and surface modifications can enhance its performance, making it valuable in various biomedical applications.

For NGCs in particular, Polycaprolactone fiber nerve guidance conduits offer a promising solution for nerve regeneration due to their controlled degradation and ability to guide axonal growth.

Figure 1 - Representation of an NGC Nerve Guidance Conduit

This study used the Henniker HPT-100 Plasma System, known for its efficacy in substrate treatment, to activate the surface of PCL-coated NGCs with oxygen plasma. This step, conducted by the researchers, facilitated subsequent silane modification by creating functional groups vital for biomaterial enhancement. The silane modification, coupled with oxygen plasma treatment, represents a sophisticated yet cost-effective approach to tailor the surface properties of biomaterials for enhanced cellular interactions and tissue regeneration.

Essentially, the surface deposition method involves oxygen plasma treatment and the addition of 11-aminoundecyltriethoxysilane (CL11) onto aligned Polycaprolactone (PCL) scaffolds. This process resulted in significant alterations in the surface chemistry and topography of PCL fibers, facilitating improved cell adhesion, differentiation, and ultimately, nerve regeneration.

Image – The Henniker Plasma HPT-100 System

The surface modification process involved treating PCL-coated substrates with oxygen plasma for 5 minutes at 20 W using the Henniker Plasma HPT-100 system. Subsequently, the substrates underwent immersion in a solution containing 2% v/v 11-aminoundecyltriethoxysilane (CL11) in isopropanol for 1 hour for silane modification.

Characterisation and Testing Techniques

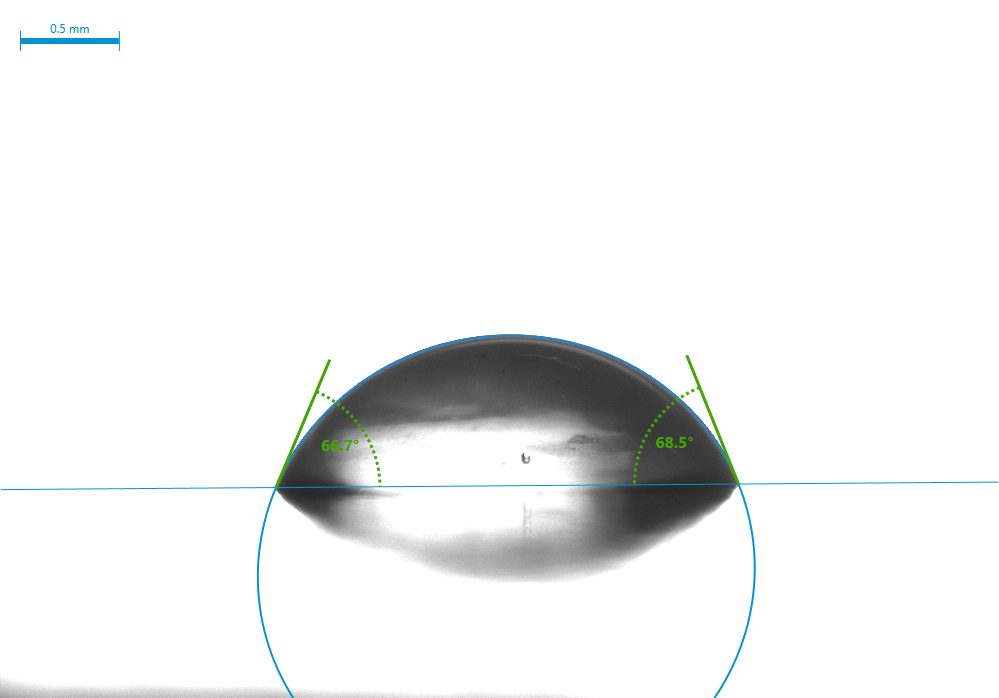

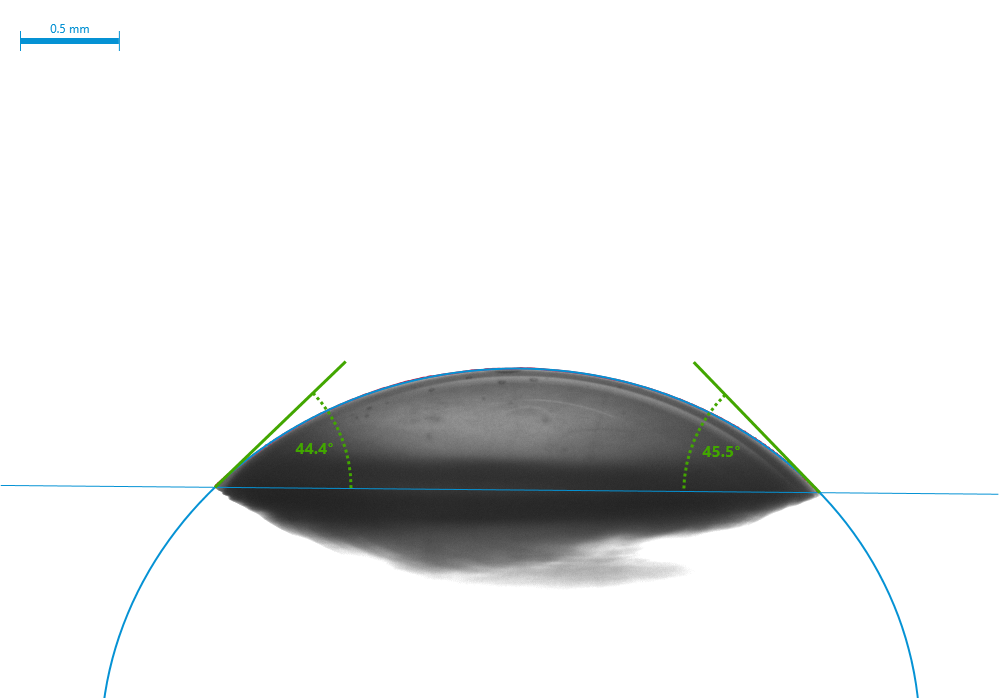

Characterisation techniques such as water contact angle measurements, atomic force microscopy (AFM), X-ray photoelectron spectroscopy (XPS), and protein adsorption assays in the paper, revealed notable changes in the surface chemistry and topography of PCL scaffolds after modification. The water contact angle results were particularly relevant to the plasma treatment, as shown in Figure 2 [1] from the paper. The decrease in the contact angle observed not only in the O2-treated PCL but also in the PCL + O2 + CL11 indicates a significant reduction in hydrophobicity, signifying increased hydrophilicity due to the plasma treatment and CL11 introduction.

Water Contact Angle Measurement

[1] ‘Figure 2. Water contact angle of PCL, PCL fibers modified with oxygen plasma and PCL fibers modified with oxygen plasma and CL11. Results are shown as presented mean (mean±SD, n=3 independent experiments; *p <0.05). A total of 9 samples, per condition, were analysed and a total of 27 contact angles were measured per condition.’

Image Credit: https://onlinelibrary.wiley.com/doi/epdf/10.1002/mabi.202300226

(For more characterisation and the full results of the atomic force microscopy (AFM), X-ray photoelectron spectroscopy (XPS), and protein adsorption assays read the full paper using the link provided Aminosilane Functionalized Aligned Fiber PCL Scaffolds for Peripheral Nerve Repair (wiley.com).)

Overall, the modifications not only enhanced cell adhesion and proliferation but also facilitated the attachment of bioactive molecules, showcasing the potential for multifunctional biomaterials tailored for diverse tissue engineering applications.

In-house Treatments

At Henniker, plasma treatments on PCL and other functional polymer groups are routine procedures conducted in-house. We present below the results of surface energy and contact angles before and after plasma treatment. An example of PCL before and after treatment demonstrates the enhanced wettability and activation achieved through this process.

PCL Polycaprolactone

| Before Plasma treatment |

After Plasma treatment |

| Contact Angle 67.56 ± 1.7O | Contact Angle 44.55 ± 0.76O |

|

|

| Surface energy 51.58 ± 1.41mN/m | Surface energy 63.75 ± 1.50mN/m |

Results and images taken from Henniker Plasma’s Materials library on PCL surface energy before and after plasma treatment – visit https://plasmatreatment.co.uk/knowledge-base/materials-library

Results and Discussion

The study demonstrates the effectiveness of plasma surface activation in enhancing biomaterials for tissue engineering, particularly in the context of peripheral nerve regeneration. The modifications induced significant alterations in the surface chemistry and topography of PCL scaffolds, thereby enhancing cell adhesion, and proliferation, and facilitating the attachment of bioactive molecules.

The results highlight the importance of surface modifications in optimising cellular interactions and tissue regeneration, paving the way for the development of advanced therapeutic strategies for nerve injuries.

References

[1] Figure 2 and the image description courtesy of DOI: 10.1002/mabi.202300226 - Aminosilane Functionalized Aligned Fiber PCL Scaffolds for Peripheral Nerve Repair (wiley.com).

Join the Conversation

Readers are referred to the original paper published in Nov 2023, available through the provided DOI link, or click the link below for further details on Henniker Plasma's HPT-100 Plasma Cleaner.

Aminosilane Functionalized Aligned Fiber PCL Scaffolds for Peripheral Nerve Repair (wiley.com)