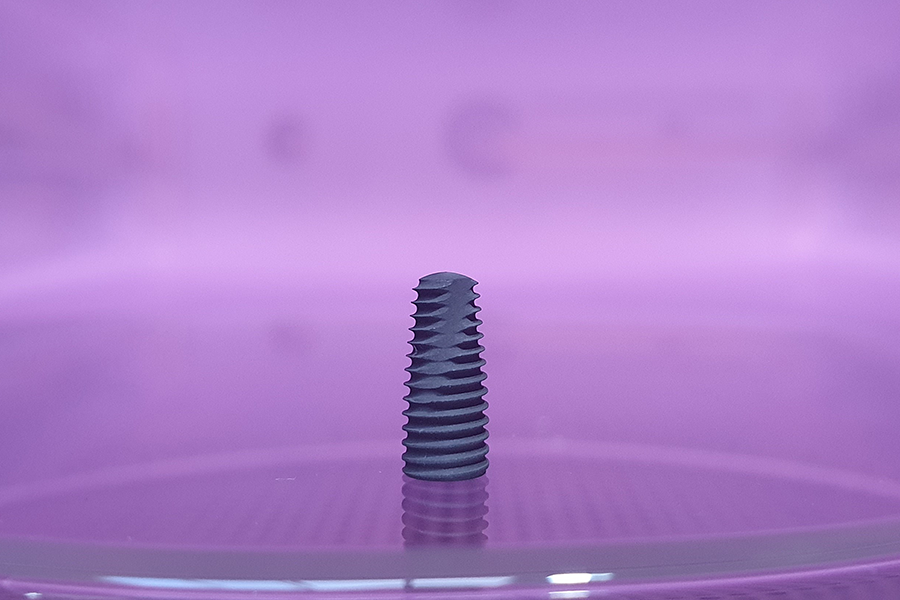

One of the challenges in dental implantology is to achieve a stable and long-lasting connection between the implant and the surrounding bone tissue. This connection, known as osseointegration, depends on various factors such as the implant material, design, surface properties, and surgical technique.

Titanium Dental Implant undergoing Plasma Treatment

Plasma treatment is a proven method to enhance the surface characteristics of dental implants and improve their osseointegration potential. Plasma treatment can modify the surface chemistry, morphology, and energy of dental implants, creating a more favourable environment for cell attachment, proliferation, and differentiation.

Plasma treatment can also reduce bacterial adhesion and biofilm formation on dental implants, which can prevent implant-related infections and improve implant survival. Therefore, plasma treatment is a valuable tool to improve the clinical outcomes of dental implant therapy, leading to better clinical outcomes and patient satisfaction.

The SLA/SA Surface Technique

The most widely used technique for increasing roughness on the surface of titanium dental implants is the SLA/SA surface technique. Developed in the late 1990s, it involves two steps: first, a large-grit sandblasting process that creates a macro-roughness on the titanium surface; second, an acid-etching process that adds a micro-roughness. The resulting surface texture provides a suitable environment for cell attachment and improves the speed and quality of osseointegration compared to smooth surfaces.

One of the drawbacks of the SLA/SA procedure is that the sandblasting process may leave some blasting material embedded into the surface of the implants, which can interfere with the osseointegration process. Another disadvantage is that the surface remains hydrophobic, which means that it repels water and may affect the initial cell attachment to implants.

The images below are taken from a scientific publication investigating the contamination effects of the SLA/SA technique on various implants. “The purpose of this study was to analyse different commercially available implant systems with a SA-modified surface and to explore the widespread notion that they have similar surface properties regarding morphology and cleanliness. SA-modified surfaces of nine implant systems manufactured by Alpha-Bio Tec Ltd, Camlog Biotechnologies AG, Dentsply Sirona Dental GmbH, Neoss Ltd, Osstem Implant Co. Ltd, Institute Straumann AG, and Thommen Medical AG were analysed using scanning electron microscopy (SEM) and energy dispersive X-ray spectroscopy (EDX) and examined for surface cleanliness.” [1]. They found that during the SLA/SA manufacturing process remnants of contamination were left embedded on the implants.

[1] Backscatter-SEM micrographs of the analysed implant systems. Note the various numbers and sizes of the Al2O3 particles (black dots) remaining on the surface following etching. Scale bar: 200 μm.

Development of a hydrophilic SLA surface treatment process

A recent collaboration between Henniker and a leading dental implant manufacturer set out to investigate and to optimise the plasma treatment process. The implants underwent process trials designed to achieve decontamination and improved hydrophilicity.

By applying a gas mixture of argon and oxygen to the implant surface, plasma treatment can be shown to remove more organic contaminants than traditional cleaning methods, while also improving wettability. Increasing implant wettability allows it to attract blood into its micropores when implanted into tissue, creating a blood clot that stabilises the implant during the initial phase of osseointegration. Osseointegration is the process of forming a direct connection between living bone and an artificial implant. The surface of this material also enhances the immobilisation of ions and the formation of an apatite layer. Apatite is a group of phosphate minerals that are found in bone and teeth. The presence of an apatite layer on the implant surface is a key factor for inducing new dentin formation.

|

Parameters of the treatment |

|

| Process Gas: | 95:5 Ar:O2 |

| Process Pressure: | 0.3mbar |

| Power: | 100% |

| Time: | 5 minutes. |

Image Shows the difference between a hydrophilic plasma treated implant (L) & an untreated implant (R).

The full plasma treatment can be performed in a short time, less than 10 minutes, using a benchtop vacuum plasma device, such as the Henniker HPT-500, that can handle various shapes and sizes of implants. With this system, the implant manufacturer was able to implement plasma treatment as part of their manufacturing process.

Dental Implants in the Henniker HPT-500 Plasma Cleaner

The process developed by the manufacturer combines the benefits of the SLA/SA technique and plasma treatment. The result is implants with superior hydrophilicity, antibacterial activity, and rapid osseointegration.

PEEK Implants and Plasma Treatment

PEEK, short for Polyetheretherketone, is a high-performance biomaterial renowned for its exceptional biocompatibility and mechanical properties. The use of PEEK in dental implants provides patients with a reliable and long-lasting solution for tooth replacement. Its lightweight nature makes it comfortable for patients, while its strength ensures durability and stability in the oral environment. Furthermore, PEEK dental implants offer natural aesthetics, seamlessly blending with the surrounding teeth.

Henniker Plasma systems are also being used to enhance the performance of PEEK dental implants, as reported in a recently published research article. This treatment again promotes better osseointegration, the process by which the implant fuses with the surrounding bone, ensuring enhanced implant stability and reduced risk of implant failure. The plasma treatment also optimises the implant's surface for improved bioactivity, which encourages the growth of bone cells around the implant, leading to a stronger and more integrated dental restoration.

Plasma treatment can be carried out chair-side with a small benchtop vacuum plasma, such as the HPT-100. The fully ‘immersive’ plasma treatment has been demonstrated to produce a significant increase in surface wettability when compared with e.g., handheld piezoelectric plasma devices [2] as shown in the chart below.

[2] Comparative plot of the resulting contact angle of different test liquids (water (ANOVA tested, p = 0.05 indicated by *), formamide, diiodomethane) and surface energies on PEEK after surface modification using atmospheric (PDD, 18 W, 120 s, 10 mm,) and low-pressure plasma (LP, 100 W, 120 s, 2 sscm) (n = 10).

Benefitting Patients

With the combined benefits of PEEK and Titanium materials, and Henniker Plasma's advanced surface treatment, dental professionals can confidently offer their patients a reliable and superior solution for restoring their smiles.

If you would like to know more about plasma treatment and dental applications, contact us today.

Click here to download our full Let's Talk About Article.

If you want to learn more about plasma treatment for dental applications click here.

References

[1]. Peter Schupbach, Roland Glauser, Sebastian Bauer, "Al2O3 Particles on Titanium Dental Implant Systems following Sandblasting and Acid-Etching Process", International Journal of Biomaterials, vol. 2019, Article ID 6318429, 11 pages, 2019. https://doi.org/10.1155/2019/6318429

[2]. Behnecke, M.; Steinert, V.; Petersen, S. Surface Characterisation of PEEK and Dentin, Treated with Atmospheric Non-Thermal PDD Plasma, Applicable for Dental Chair-Side Procedures. Plasma 2021, 4, 389-398. https://doi.org/10.3390/plasma4030028