In plasma coatings, a nano-scale polymer layer is formed over the entire surface area of an object placed in the plasma. The plasma coating process takes just a few minutes. The coating produced is typically less than 1/100th thickness of a human hair, colourless, odourless and doesn’t affect the look or feel of the material in any way. It is a permanent coating too, being bound to the material surface on an atomic scale.

Plasma coatings are one of the most exciting areas of plasma technology, offering enormous potential to enhance a material’s function and value over a wide range of applications. They deliver two main categories of surface property: totally liquid (water & oil) repellent, or totally wettable.

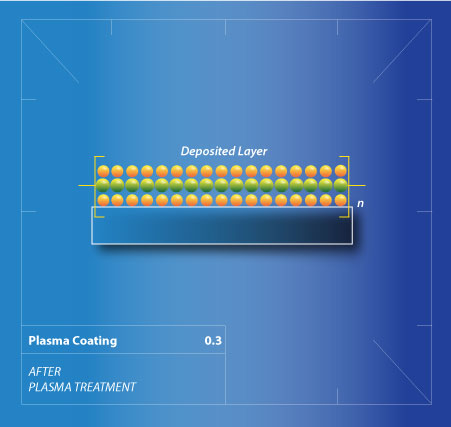

How plasma coatings work

Monomers are introduced with the plasma feed gas. Monomers are small molecules which will, under the correct conditions, bond together to form polymers. Plasmas create the right conditions at the surface of the material for this to happen both quickly and efficiently. Different monomers are used to produce hydrophobic and hydrophilic surfaces.

Before Plasma Treatment

Before Plasma Treatment During plasma treatment

During plasma treatment  After plasma treatment

After plasma treatmentPlasma Coatings Explained

Plasma Coatings Explained.

The fifth in our series of videos about plasma treatment technology, this video explains how plasma coatings work and the results you can achieve.

Hydrophobic Coatings

Permanent hydrophobic surfaces are rapidly finding new applications all the time. Liquid repellent coatings currently enhance products in the textile, medical device, ophthalmic and consumer electronics industries to name but a few.

Plasma coating is suitable for e.g.:

- general plastics and rubber

- performance textiles

- filtration media

- metals, glass, ceramics and composites

- medical plastics

- consumer electronics plastics

- automotive components

- aerospace components

Liquid repellent plasma coatings

Untreated surface

Untreated surface Plasma treated surface

Plasma treated surfaceSpecific treatments render surfaces totally repellent to water, solvents and oils.

Hydrophilic plasma coatings

Untreated surface

Untreated surface Plasma treated surface

Plasma treated surfaceHydrophilic plasma treatments render surfaces permanently wettable.